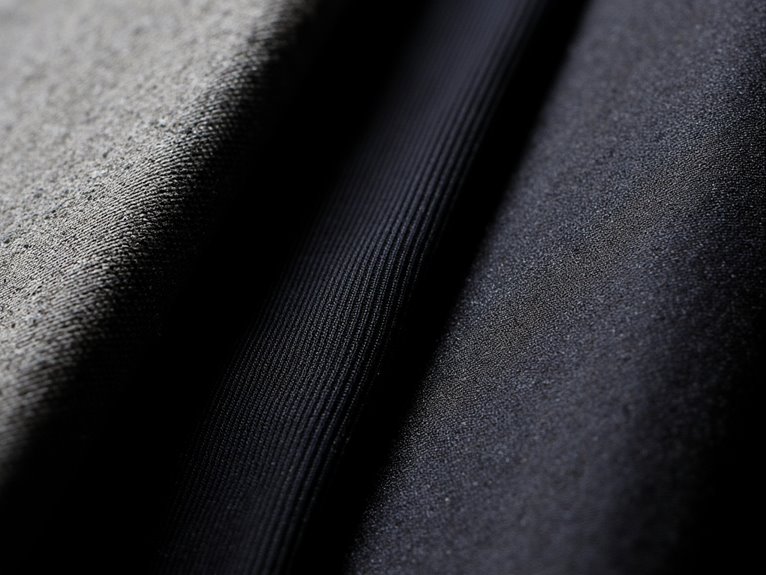

Fabric Technologies: Ripstop, Stretch, Abrasion Resistance

You’ll find three critical fabric technologies that define performance gear durability and functionality. Ripstop construction uses reinforcement threads woven at 5-8mm intervals to prevent tear propagation, while four-way stretch fabrics with elastane fibers extend up to 500% for enhanced mobility. Abrasion resistance testing through Martindale, Wyzenbeek, and AATCC methods determines long-term durability under stress. These technologies combine in modern textiles to deliver superior strength-to-weight ratios and water resistance, with the technical specifications below revealing ideal applications.

We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 27th January 2026 / Images from Amazon Product Advertising API.

Notable Insights

- Ripstop fabric features reinforcement threads woven every 5-8mm in a crosshatch pattern to prevent tears from spreading.

- Stretch fabrics use elastane fibers to provide two-way or four-way stretch, extending up to 500% while maintaining recovery.

- Advanced water-resistant coatings block moisture and particles while preserving fabric breathability and maintaining superhydrophobic properties.

- Superior strength-to-weight ratios in modern fabrics reduce material costs while enhancing performance in aerospace and automotive applications.

- Abrasion resistance testing uses Martindale, Wyzenbeek, and AATCC methods to measure durability cycles until yarn breaks or wear appears.

Understanding Ripstop Fabric Construction and Materials

When you examine ripstop fabric under close inspection, you’ll notice a distinctive crosshatch pattern that sets it apart from conventional textiles. This grid consists of thicker reinforcement threads woven at 5 to 8 mm intervals throughout a lighter base fabric.

The heavier threads act as barriers that contain tears, preventing them from spreading across the material.

Modern manufacturing techniques have greatly improved fabric aesthetics by making reinforcement threads less visually obvious while maintaining structural integrity.

Nylon and polyester dominate ripstop applications due to their superior strength-to-weight ratios. Cotton blends offer enhanced breathability but sacrifice some tear resistance. Many ripstop fabrics receive additional treatments to enhance water repellency or flame resistance properties.

The grid structure disperses stress over wider areas, minimizing localized damage. Originally developed during World War II as a replacement for silk in military parachutes, ripstop technology has proven its effectiveness in demanding applications. You’ll find ideal performance when grid spacing and thread thickness are precisely balanced for specific applications.

Strength-to-Weight Ratio Benefits in Performance Applications

Although ripstop fabric’s crosshatch construction provides excellent tear resistance, its true advantage emerges when you consider the strength-to-weight ratio that makes it indispensable in performance applications.

This ratio enables materials to support massive loads while remaining lightweight, directly improving efficiency across demanding sectors. Your material selection determines whether components maximize load capacity without exceeding critical weight limits.

Lightweight structures reduce raw material costs and enhance power-to-weight performance in vehicles, improving acceleration and speed. In aerospace applications, every gram saved translates to fuel efficiency gains and better maneuverability.

In aerospace applications, every gram eliminated directly improves fuel efficiency and aircraft maneuverability while reducing operational costs.

Performance optimization becomes achievable when ripstop fabrics deliver structural integrity without bulk. These materials prove critical in sporting goods, automotive components, and defense applications where weight savings directly correlate with operational effectiveness and reduced transportation costs.

Water Resistance and Protective Coating Technologies

While ripstop fabrics excel in strength applications, their performance reaches new levels when enhanced with advanced water resistance and protective coating technologies. You’ll find today’s waterproof advancements utilize fluorine-free formulations that maintain fabric breathability while blocking water, oil, and particulates. These durable coatings consist of inorganic molecules that encase individual fibers, creating superhydrophobic properties without altering texture or appearance.

| Coating Type | Repellency Duration | Environmental Impact | Special Features |

|---|---|---|---|

| Fluorine-Free DWR | 50+ wash cycles | PFAS-free, VOC-free | UV protection, flame retardancy |

| Water-Based Formulations | Extended periods | Environmentally safe | Virus-blocking capabilities |

| C6 DOR Treatments | 50 washes | Low VOC emissions | Icephobic properties |

| PU/PVC Coatings | Long-term | Moderate impact | Lightweight flexibility |

Modern treatments resist physical wear while preserving tensile strength and thermal comfort management across outdoor gear applications.

Stretch Fabric Integration for Enhanced Mobility

As moisture-wicking and protective coatings enhance fabric performance, stretch technology revolutionizes how textiles respond to human movement.

You’ll find two primary stretch configurations: two-way stretch operates along a single axis, while four-way stretch provides bi-directional elasticity. Four-way stretch fabrics deliver superior body movement adaptation, making them essential for activewear performance applications.

Four-way stretch technology provides bi-directional elasticity that adapts to body movement, making it essential for high-performance activewear applications.

Elastane fibers integrated into fabric construction provide the mechanical foundation for stretch capabilities.

These fibers enable your garments to extend up to 500% of their original length while maintaining recovery properties. The elasticity supports dynamic muscle movement in both vertical and horizontal directions, effectively enlarging your range of motion during athletic activities.

This enhanced mobility reduces muscle strain and joint restriction, allowing longer activity duration while minimizing injury risk through improved fabric conformity. Similar to how lightweight construction under 1.5 pounds per pair reduces fatigue during extended physical activities, stretch fabrics minimize restriction for sustained performance. Just as hiking footwear benefits from flexible soles that adapt to various foot shapes, stretch fabrics conform to your body’s natural contours for optimal performance during extended physical activities.

Abrasion Resistance Testing and Durability Standards

Enhanced mobility means nothing if your fabric deteriorates under regular use.

You’ll encounter three primary abrasion testing methods when evaluating fabric durability. The Martindale test uses cyclic rubbing in a figure-8 pattern against wool abradant. The Wyzenbeek test employs back-and-forth motion with cotton duck fabric until yarn breaks occur. AATCC TM093 subjects fabric to rapid impacts inside rotating chambers.

These durability metrics measure cycles before two yarn breaks or appreciable wear appears. ASTM D4966-22 and ASTM D4157 serve as industry standards, while BS 5690 governs European testing protocols.

You’re evaluating relative performance rather than absolute wear predictions. Significant differences in test scores correlate with noticeable durability variations, though small score differences offer limited predictive value for real-world applications.

Frequently Asked Questions

How Do I Properly Wash and Care for Ripstop Fabric Garments?

Use cold water and delicate cycles for proper fabric maintenance. Avoid bleach and fabric softeners. Air dry flat, don’t tumble dry. These washing tips preserve ripstop’s coatings and prevent fiber damage effectively.

What’s the Typical Lifespan of Ripstop Fabric in Harsh Outdoor Conditions?

Your ripstop fabric’s durability typically lasts 1-5 years in harsh outdoor conditions. Ripstop durability depends on UV exposure, material quality, and maintenance, while outdoor performance degrades faster with intense sun and moisture exposure.

Is Ripstop Fabric Suitable for People With Sensitive Skin or Allergies?

Ripstop fabric isn’t ideal if you’ve got sensitive skin or allergies. Its synthetic fibers can cause allergy reactions and skin irritation through trapped moisture, chemical treatments, and increased friction against your skin.

On a final note

You’ll find that modern fabric technologies work together to create superior performance gear. Ripstop construction prevents tear propagation while maintaining lightweight properties. Stretch integration guarantees you won’t sacrifice mobility for durability. Abrasion resistance testing validates real-world performance standards. When you’re selecting technical fabrics, consider how these three technologies complement each other. Your gear’s performance depends on understanding these specifications and choosing fabrics that meet your specific application requirements.