Powering Sensitive Electronics: Surge Protection, Pure-Sine Inverters, and Best Practices

You’ll need multi-layered surge protection to safeguard sensitive electronics from voltage spikes that can exceed 169 volts and cause immediate damage. Install Type 2 panel-mounted SPDs for whole-home protection, complemented by Type 3 point-of-use devices positioned at least 30 feet from electrical panels. Pure-sine wave inverters delivering 90%+ efficiency provide clean AC power during outages, while proper clamping voltage ratings and energy absorption capacity guarantee the best protection. Regular quarterly inspections and IoT monitoring systems help maintain peak performance and predict component failures before they occur.

We are supported by our audience. When you purchase through links on our site, we may earn an affiliate commission, at no extra cost for you. Learn more. Last update on 18th January 2026 / Images from Amazon Product Advertising API.

Notable Insights

- Voltage surges can cause immediate damage or cumulative degradation to sensitive electronics, with 70% of facilities experiencing surge-related downtime.

- Pure sine wave inverters provide utility-grade AC power with 90%+ efficiency and built-in protections for reverse polarity, over-voltage, and short circuits.

- Type 2 SPDs mount on load sides for whole-home protection, while Type 3 devices offer point-of-use protection for individual equipment.

- Lower clamping voltage and faster response times provide superior protection; regular maintenance inspections every 3-6 months ensure continued functionality.

- IoT monitoring systems enable predictive maintenance through real-time performance tracking and automated alerts for voltage irregularities and component degradation.

Understanding Power Surge Risks and Their Impact on Electronic Equipment

What happens when voltage levels spike beyond your electronic equipment’s design limits? Your devices face potential damage or complete failure. Standard residential AC normally peaks at 169 volts, but surge sources like lightning strikes, electrical load switching, and utility grid faults push voltage far beyond safe thresholds.

These surge effects manifest in multiple ways. Circuit boards and microcircuits suffer immediate damage, while smaller repeated surges cause cumulative degradation that shortens equipment lifespan. You’ll notice symptoms like device shutdowns, flickering displays, or burning odors when integrated circuits experience voltage stress.

The financial impact is substantial. Lightning-related electronics damage averages over $21,000 per insurance claim. Approximately 70% of facilities experience downtime from voltage surges, with 34% of unplanned outages directly linked to surge-induced equipment failures. Distinguishing between direct lightning strikes and high voltage surges requires expert assessment, as lightning is the actual reported cause in only 2% of consumer claims. Implementing surge protective devices is essential for maintaining reliable operation and preventing costly equipment replacement in critical infrastructure.

Types of Surge Protection Devices and Their Applications

Understanding surge risks leads directly to selecting the right protection devices for your specific needs.

Low voltage devices include surge protector power strips with 6-12 outlets for electronics and wall-mount protectors offering 2-6 outlets with compact designs.

Low voltage surge protectors range from 6-12 outlet power strips for electronics to compact 2-6 outlet wall-mount designs.

Panel-mounted SPDs like the Eaton CH Ultra require 50-amp breakers and install directly into your main electrical panel for whole-home protection.

High voltage protection utilizes three industry classifications.

Type 1 SPDs handle 1000 volts or less at service entrances. Type 2 SPDs mount on load sides for 600 volts or less, requiring licensed electrician installation.

Type 3 SPDs provide point-of-use protection for individual devices, positioned at least 30 feet from electrical panels.

This layered approach creates extensive protection from service entrance to individual electronics.

Key Performance Metrics for Selecting Surge Protectors

When choosing surge protection devices, five critical performance metrics determine how effectively they’ll safeguard your sensitive electronics.

Surge ratings indicate maximum current capacity without device damage-higher ratings extend operational life through repeated transient events.

Maximum Continuous Operating Voltage (MCOV) defines the highest voltage level before conduction begins. Select MCOV ratings above your system’s normal operating voltage to prevent premature failure during voltage swells.

Clamping voltage represents when protection activates-lower values provide superior protection by limiting voltage spikes more effectively.

Energy absorption capacity measures total cumulative energy the device handles before failure.

Response time determines reaction speed after transient detection. Faster response times reduce sensitive equipment exposure to damaging voltages, particularly critical for computers and telecommunications devices.

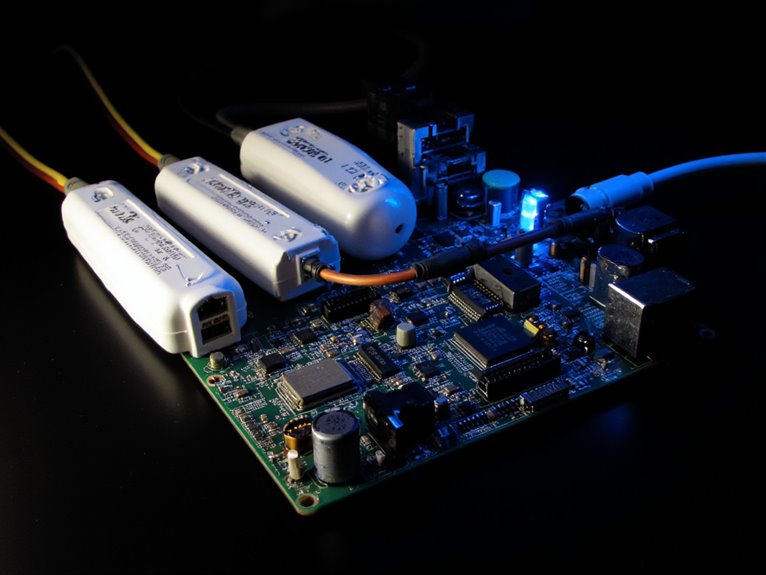

Pure-Sine Wave Inverters for Clean Power Delivery

Pure sine wave inverters represent the gold standard for converting DC battery power into clean AC electricity that matches utility-grade power quality.

You’ll get superior sine wave efficiency exceeding 90%, minimizing energy loss during conversion.

These inverters use Pulse Width Modulation (PWM) technology to create high-frequency square waves, then filter them into smooth sine waves with less than 3-5% Total Harmonic Distortion.

Advanced PWM technology generates precise high-frequency pulses, then sophisticated filtering transforms them into clean sine waves with minimal harmonic distortion.

Inverter compatibility becomes essential when powering sensitive electronics like medical equipment, audio devices, and precision instruments.

You can select output voltages between 100-240VAC and frequencies of 50Hz or 60Hz to match your specific requirements.

Models range from 1500W to 5000W continuous power, with surge capabilities reaching 3600W.

Built-in protections include reverse polarity, over-voltage, short circuit, and over-temperature safeguards for reliable operation.

Installation Considerations and Cost Factors

Three primary cost components determine your total investment in surge protection: equipment, professional installation, and potential electrical system upgrades.

Type 1 protectors cost $100-$500+ for units, reaching $800 installed. Type 2 models range $60-$300, totaling $200-$450 with labor. Professional installation averages $140-$300, with electricians charging $50-$130 hourly plus $100-$200 service fees.

Installation challenges arise when older homes need 200-amp panel upgrades, adding $500-$4,000. Proper electrician qualifications include licensing, bonding, and surge protection experience to guarantee code compliance and warranty validity.

Panel compatibility must be verified beforehand to prevent costly rework. Homes with subpanels require additional protectors, increasing material and labor costs. Higher NEMA ratings provide superior protection but increase prices proportionally.

Maintenance Strategies and Best Practices for Long-Term Protection

You can’t simply install surge protectors and forget about them-these devices require systematic maintenance to guarantee they’ll protect your electronics when power events occur.

Establishing regular inspection schedules every 3-6 months helps you catch degraded performance before complete failure, while understanding replacement timing indicators like failed status lights or post-surge damage prevents gaps in protection.

Modern IoT monitoring systems now offer automated oversight of your surge protection network, sending real-time alerts about device status and environmental conditions that could compromise performance.

Regular Inspection Schedules

While surge protection devices can’t protect your equipment if they’re silently failing, establishing a consistent inspection schedule guarantees your SPDs remain operational when you need them most. Monthly visual inspections catch early warning signs like indicator light failures or physical damage. Your inspection frequency should intensify based on environmental conditions and equipment criticality.

| Inspection Type | Frequency | Key Checkpoints |

|---|---|---|

| Visual Assessment | Monthly | Indicator lights, physical damage, discoloration |

| Electrical Testing | Quarterly | Clamping voltage, grounding integrity, multi-mode protection |

| Terminal Inspection | Quarterly | Torque specifications, connection tightness, corrosion |

| Full System Validation | After surge events | Complete functionality, documentation, replacement needs |

Developing thorough inspection checklists guarantees you don’t miss critical failure indicators. Document all findings to track performance trends and plan proactive replacements.

Replacement Timing Indicators

Knowing when to replace surge protection devices requires monitoring specific visual and performance indicators that signal compromised protection capability.

Watch for “Protected” LED status changes-green lights turning off indicate failed MOV components inside your device. Automatic shutoff models permanently cutting power to outlets signal end-of-life protection failure.

Physical damage like discoloration, cracks, or melting demands immediate replacement regardless of electrical functionality.

MOV degradation occurs cumulatively through repeated surge absorption, making replacement indicators essential for proactive planning. Your surge protector’s joule rating decreases progressively until protection becomes ineffective.

Manufacturer warranties typically span 3-5 years, providing replacement timing guidance. Pre-warning indicators and remote monitoring contacts enable scheduled maintenance before complete failure.

Document installation dates and surge events to optimize replacement schedules for your specific electrical environment.

IoT Monitoring Systems

Modern IoT monitoring systems transform surge protection maintenance from reactive replacement schedules into proactive, data-driven strategies that maximize equipment longevity and minimize unexpected failures.

You’ll gain unprecedented visibility into your surge protection infrastructure through centralized platforms that continuously track device health metrics. IoT analytics reveal performance patterns that predict component degradation before catastrophic failures occur. Digital twins create virtual replicas of your surge protection devices, enabling remote diagnostics and real-time assessment.

Key monitoring capabilities include:

- Real-time performance tracking with automated alerts for voltage irregularities and component stress

- Predictive maintenance scheduling based on actual device wear patterns rather than arbitrary timelines

- Centralized dashboard integration displaying Overall Equipment Effectiveness and Mean Time Between Failures

- Multi-level alert systems delivering critical notifications via SMS, email, and push notifications

This data-driven approach reduces maintenance costs while ensuring superior protection for your sensitive electronics.

Frequently Asked Questions

Can Surge Protectors Be Used With Generators and Backup Power Systems?

Yes, you can use surge protectors with generators if there’s generator compatibility with your system’s wattage and outlets. Confirm backup system safety by checking for floating neutral issues and following proper installation guidelines.

Do Surge Protectors Work During Power Outages or Brownout Conditions?

Surge protectors don’t work during power outages since they can’t supply power, and they only provide partial protection during brownout conditions without correcting voltage drops. You’ll need UPS systems for continuous power.

Can Multiple Surge Protectors Be Daisy-Chained Together Safely?

No, you shouldn’t daisy chain surge protectors safely together. Daisy chain safety regulations like OSHA and NEC prohibit this practice. Surge protector compatibility issues include overloading, fire risks, and reduced protection effectiveness.

On a final note

You’ve learned the essential components for protecting sensitive electronics from power disturbances. Proper surge protection devices rated at 2,000+ joules provide your first defense line. Pure-sine wave inverters deliver clean AC power with less than 3% total harmonic distortion. You’ll maximize equipment lifespan by installing whole-house suppressors, maintaining grounding systems annually, and monitoring voltage levels regularly. These practices guarantee your valuable electronics operate safely within manufacturer specifications.